PRODUCT CATEGORIES

- Small core protection film

- Marble/Countertop Protective Film

- Carpet Protective Film

- Sheet Metal Protection Film

- HVAC Duct Protection Film

- PVC Plastic/Aluminum Extrusion Profile Protection Film

- ACP Aluminum Composite Panel PE Protective Film

- Floor and Hard Surface PE Protective Film

- Glass Protective Film

- Stainless Steel PE Protective Film

- Collision Wrapping Film

- Mirror Safety Backing Film

- Metal Surface PE Protective Film

- Plastics PE Protective Film

- Rough Surface PE Protective Film

- Self-adhesive film

- Stucco Masking Tape

- Sandwich Panel Protection Film

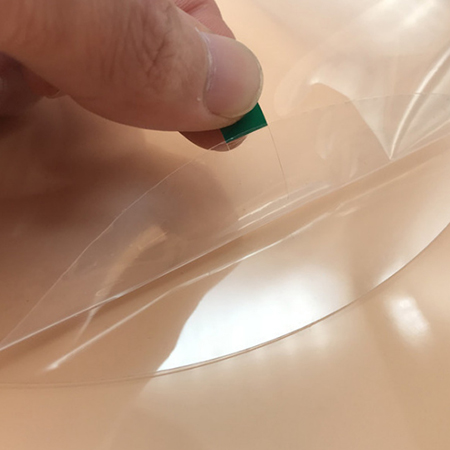

Plastic production process of Home appliance electronics pe protective film for glossy plastics

Plastics PE Protective Film:

Plastics are widely used in both industry and home usage. To keep plastics surface safe, from manufacturing to customer’s hands, carefully dealing with is important. Contaminants, industrial solvents,scratches and painting pollution can devaluing the product and add your cost. That’s why HNHN’s protective film seems necessary. Our protective film can customize your special need in order to protect your products and save your value.In specific, the assembly of home appliances and electronic device can largely save labor resources and profit value with temporary protective film in the whole process.

DIMENSION:

(20-1700) mm × (500-1000)m × (0.02-0.12)mm (width×length×thickness)

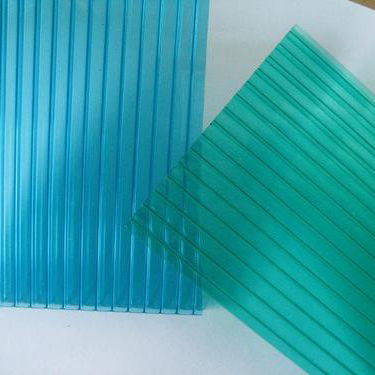

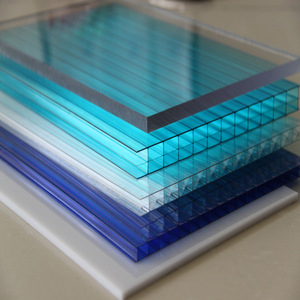

COLOR:

transparent, blue, milky white, etc (customized)

QUICK DETAIL

-

materialPE

-

typeadhesive film

-

usagesurface protection

-

featurewater proof

-

hardnesssoft

-

processing typeblow molding

-

transparencytransparent

-

place of originZhejiang,China(mainland)

-

brand nameHNHN

-

production typefactory manufacturer

-

certificateSGS,CE,ISO9001

-

product nameprotective film for plastics

-

packingcarton,pallet or air cushioned film

-

colorblue, transparent

-

thickness0.02-0.12mm(customized)

-

length500m-1500m(customized)

-

width20mm-1700mm(customized)

-

adhesion/

-

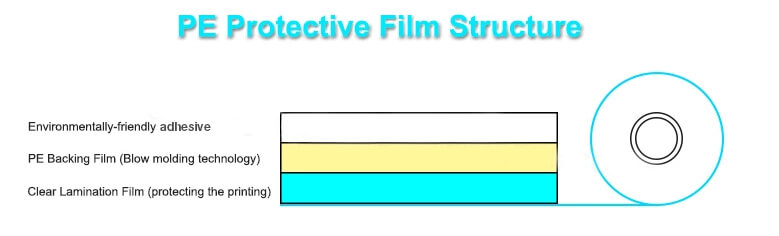

WHAT IS OUR PRODUCT FEATURE?

1. We use 100% virgin raw material in every production processing.

2. The technicans in our company all have over 15 years experience in the protective film fields.

3. Leave no residue glue after peeling off.

4. Stable adhesive strength.

5. excellent flexibility, good wettability, No-glue residue and ghosting after peel off

WHAT IS PRODUCT'S ADVANTAGE?

1. Easily apply and easily peel off.

2. Minimal change in adhesive strength ensures easy peeling.

3. After peeling off your product remains perfectly clean and untouched.

4. Provide a protective barrier to scratch,damage and dirt at the process of transportation, production and installation.

5. You can save labor resources in working and gain profit

SPECIFICATION

ABOUT US

-

Rich experience with OEM&ODM

-

Competitive price with best quality

-

24 hours online to solve your problem

-

Ontime delivery time

-

After-sale service