What is PE protective film?

2020-03-06

What is our PE protective film?

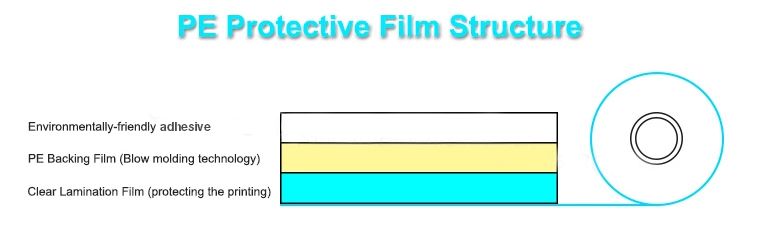

PE, full name polyethylene, is the simplest molecular structure of organic compounds and is the most widely used polymer material in the world. It is a non-toxic and pollution-free green environmental protection product. PE protective film is made of special polyethylene (PE) plastic film as the substrate, coated with pressure sensitive adhesive. Professional protective film manufacturers will customize and make different protective films based on the roughness of the customer's product surface, including the use of adhesive. We have water-based adhesive, solvent-based adhesive and rubber based-adhesive.

The biggest advantage of PE protective film is that the protected product is not contaminated, corroded, scratched during the production, processing, transportation, storage and use, and protects the original smooth and shiny surface, thereby improving product quality and market competitiveness.

Performance

According to the viscosity, it is mainly divided into: ultra-low viscosity protective film, low-viscosity protective film, medium-low viscosity protective film, medium-viscosity protective film, high-viscosity protective film, ultra-high-viscosity protective film

1. Ultra-low viscosity protective film (i.e. micro-bottom adhesion):

Characteristics: thick (≥0.03m ± 0.03), width (≤1.3), height (100-1500), substrate (PE), peel strength (≤5g / cm), temperature resistance (60), Elongation (> 400)

Uses: easy to use, easy to stick and tear, no residual glue phenomenon, suitable for organic plates, instruments, displays, glass lenses, plastic lenses, etc.

2. Low-viscosity protective film

Characteristics: Thick (≥0.03m ± 0.03), width (≤1.3), height (100-1000), substrate (PE), peel strength (10-20g / cm), temperature resistance (60) , Elongation (> 400)

Uses: stable adhesion, good adhesion, good peeling performance, no glue residue, suitable for steel mirror plate, titanium metal, glossy plastic plate, silk screen, name plate, etc.

3. Low and medium viscosity protective film

Characteristics: thick (≥0.03m ± 0.03), width (≤1.3), height (100-1000), substrate (PE), peel strength (30-50g / cm), temperature resistance (60) , Elongation (> 400)

Uses: stable adhesion, good adhesion, good peeling performance, no residual glue, suitable for furniture Polaroid board, stainless steel plate, ceramic tile, marble, artificial stone, etc.

4. Medium-viscosity protective film

Characteristics: thick (≥0.05 + 0.03), width (≤1.3), height (100-1000), substrate (PE), peel strength (60-80g / cm), temperature resistance (60) , Elongation (> 400)

Uses: stable adhesion, good adhesion, good peeling performance, no residual glue, suitable for fine-grained frosted boards and general surface protection of difficult-to-stick materials.

5. High-viscosity protective film

Features: thick (≥0.05 + 0.03), width (≤1.3), height (100-800), substrate (PE), peel strength (80-100g / cm), temperature resistance (60) , Elongation (> 400)

Uses: stable adhesion, good adhesion, good peeling performance, no residual glue, suitable for fine-grained matte board, aluminum-plastic board, hard-to-stick plastic board, etc.

6. Ultra-high viscosity protective film

Characteristics: thick (≥0.04 ± 0.03), width (≤1.3), height (100-800), substrate (PE), peel strength (100g / cm or more), temperature resistance (60), Elongation (> 400).

Uses: Very high viscosity. Water-based acrylic is used as pressure-sensitive adhesive, which is easy to use, easy to stick and tear, and has no residual glue. It is suitable for hard-to-stick materials such as rough aluminum plate.

Requirements

1. Suitable viscosity: easy to stick and tear;

2. Stable peeling force: small change over time, that is, the smaller the increase in peeling force, the better;

3. Good weather resistance: the use period is up to half a year to one year under sunlight exposure conditions;

4. Long storage period: stored in the warehouse for more than one year, no change in quality;

5. Non-pollution and non-corrosion: the adhesive is inert and will not chemically react with the surface of the adhered material;

6, excellent mechanical properties: tensile strength, elastic modulus, elongation, etc. that meet user requirements.